- Home

- Products

- Green Line

- Hose & Tubing

- Tank Truck

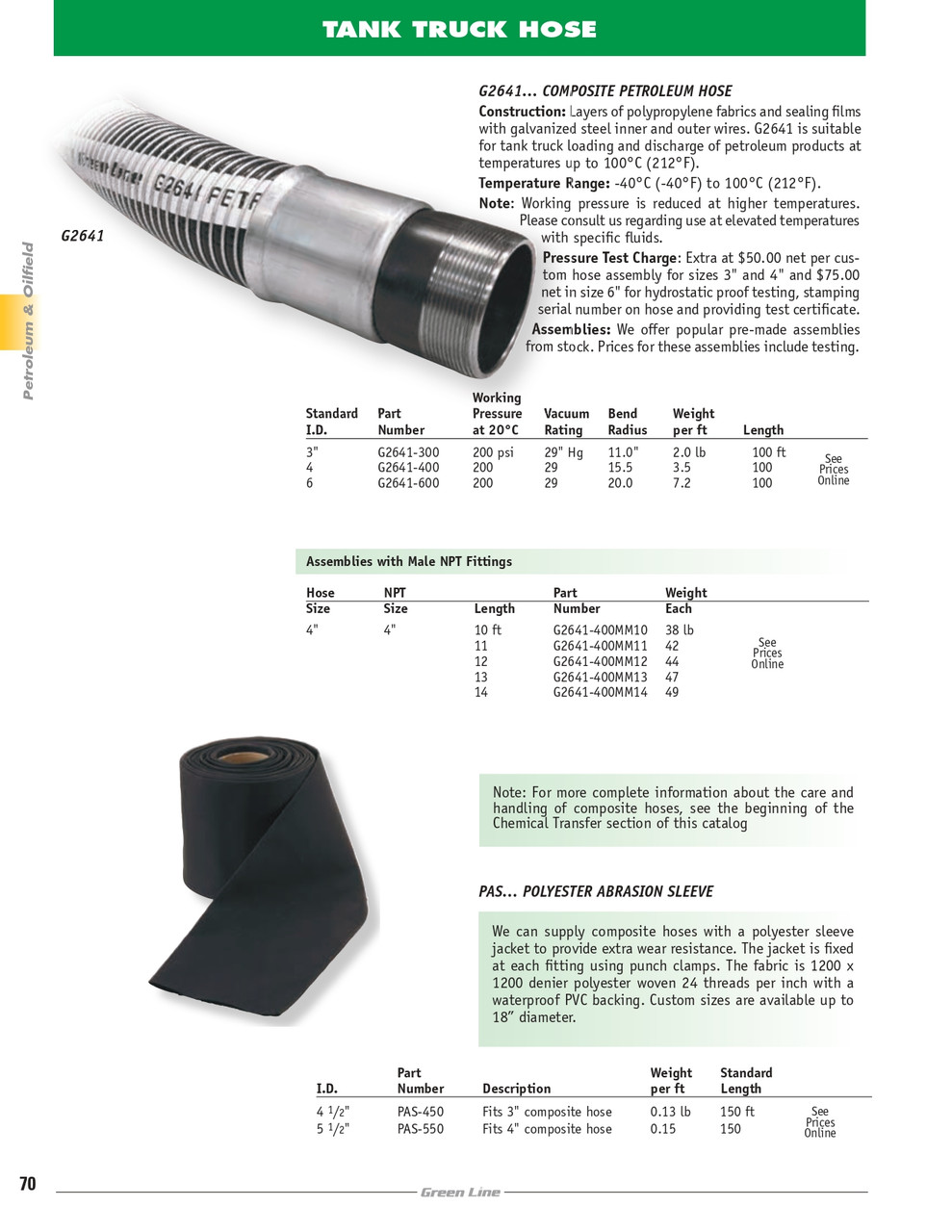

- 4 x 4" x 13' Composite Petroleum Hose Assembly G2641-400MM13

4 x 4" x 13' Composite Petroleum Hose Assembly G2641-400MM13

Greenline

MSRP:

Now:

$1,265.47

(You save

)

- SKU:

- GRN G2641-400MM13

- Weight:

- 47.00 LBS

Recommended

-

4 x 4" x 12' Composite Petroleum Hose Assembly G2641-400MM12

MSRP:Now: $1,204.32

4 x 4" x 10' Composite Petroleum Hose Assembly G2641-400MM10

MSRP:Now: $1,082.02

4 x 4" x 11' Composite Petroleum Hose Assembly G2641-400MM11

MSRP:Now: $1,143.17