Product Description

Product Features

1) Bored, keyed and set screw style ~ clearance or interference fit

2) Bushing style (Dodge®, Browning® & QD style taper lock bushings)

3) Splined style

4) Mill-motor style (tapered shaft)

Product Videos

Custom Field

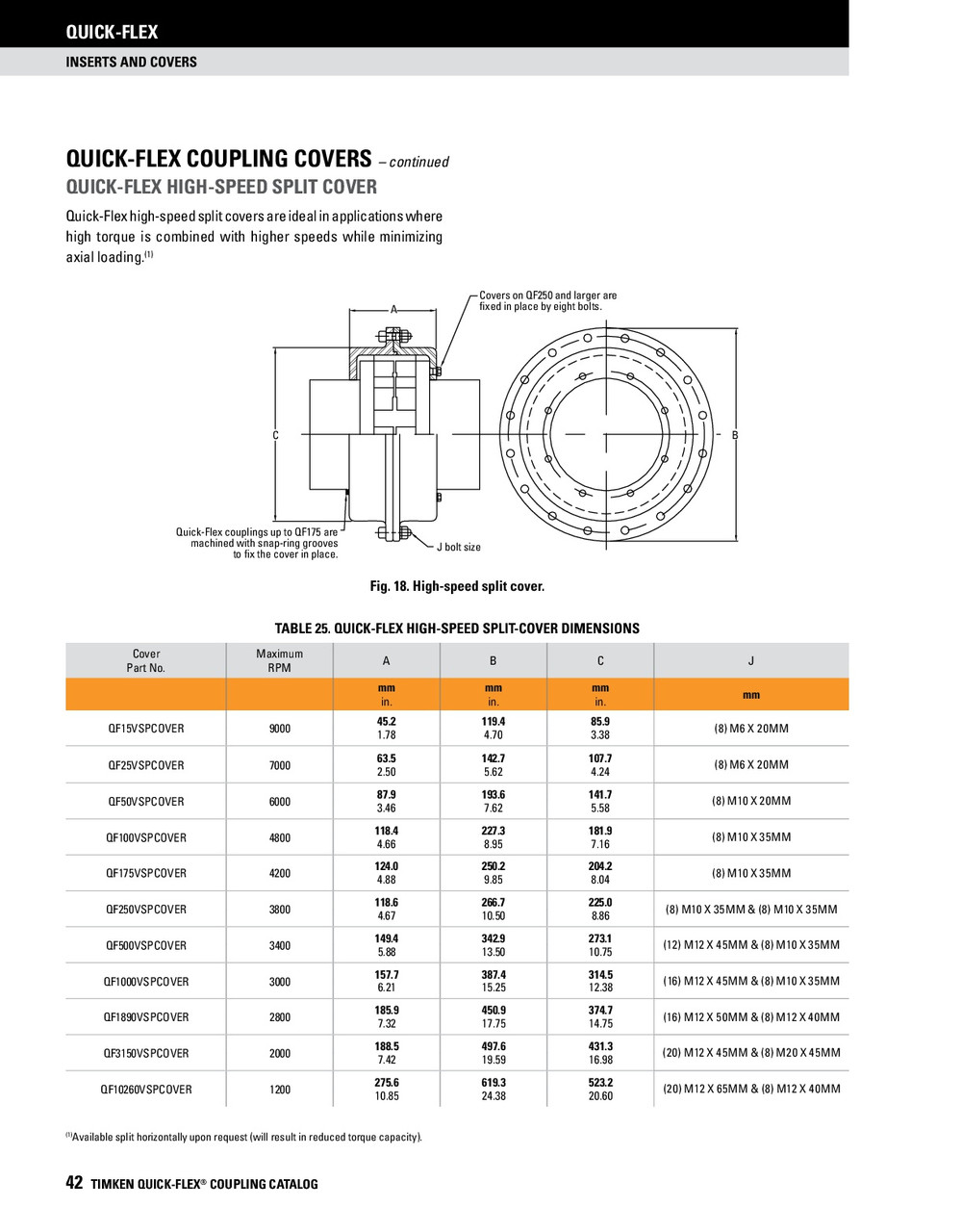

Component type Cover

Classification High speed

Material Steel

Features Split cover