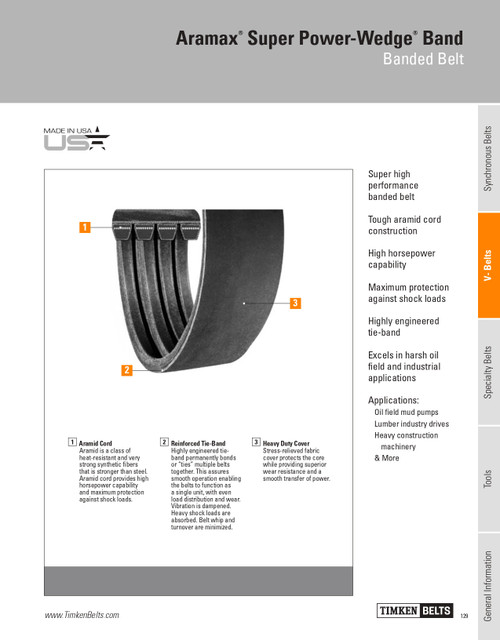

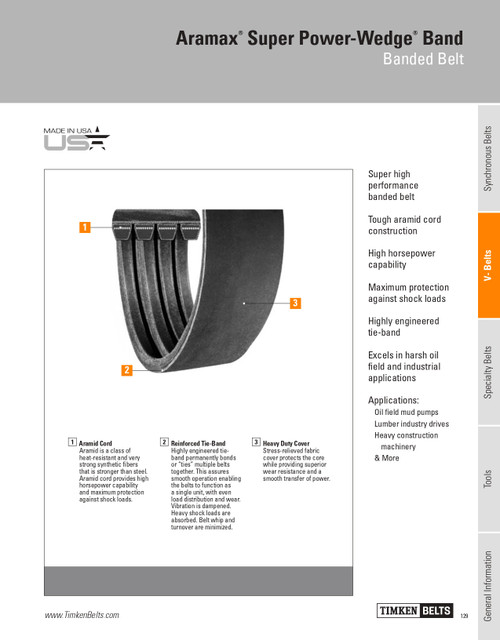

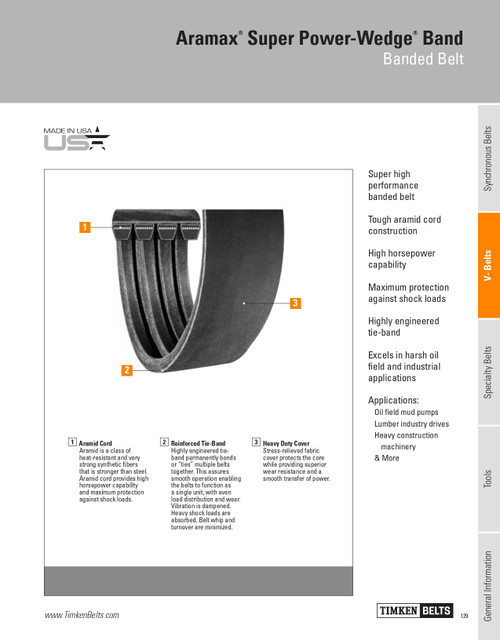

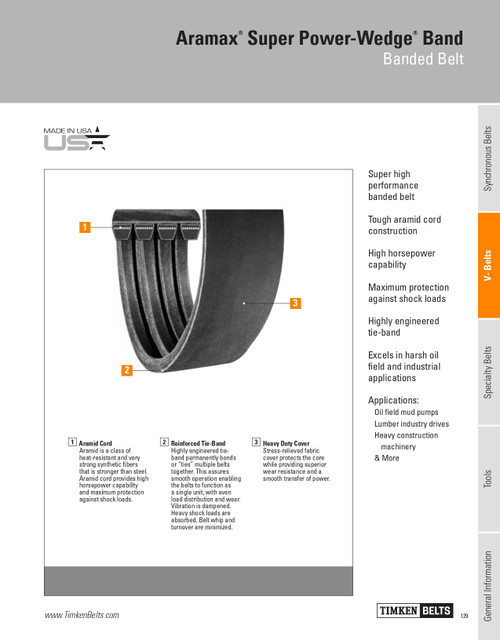

Product Description

Please use this link to use the Timken belt interchange/cross-reference TIMKEN BELTS INTERCHANGE

Please use this link to use the Timken belt interchange/cross-reference TIMKEN BELTS INTERCHANGE