- Home

- Products

- Lovejoy

- Power Transmission

- Sheaves

- Aluminum

- Variable Speed

- 5/8" Shaft Lovejoy® Aluminoline® Model 160 Spring Loaded Driver Pulley 160-5/8-PULLEY

5/8" Shaft Lovejoy® Aluminoline® Model 160 Spring Loaded Driver Pulley 160-5/8-PULLEY

Timken

MSRP:

Now:

$1,478.20

(You save

)

- SKU:

- TIM 160-5/8-PULLEY

- UPC:

- UPC 0685144185730

- Weight:

- 3.75 LBS

- Series:

- 160

- Shaft diameter:

- 5/8"

- Keyway size:

- 3/16 x 3/32"

- Outer diameter:

- 6.00"

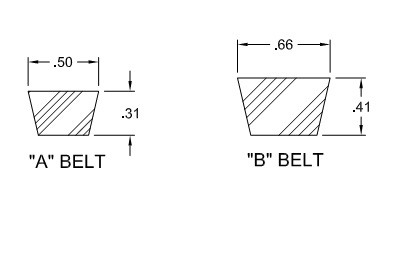

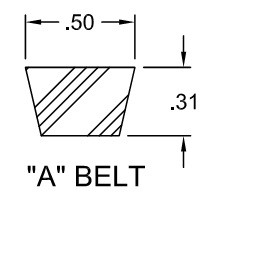

- Belt size:

- "A" belt

- Type:

- Variable speed drive

Series 160

Shaft diameter 5/8"

Keyway size 3/16 x 3/32"

Outer diameter 6.00"

Belt size "A" belt

Type Variable speed drive

Recommended

-

3/4" Shaft Lovejoy® Aluminoline® Model 160 Spring Loaded Driver Pulley 160-3/4-PULLEY

MSRP:Now: $1,478.20

5/8" Shaft Lovejoy® Aluminoline® Model 170 Spring Loaded Driver Pulley 170-5/8-PULLEY

MSRP:Now: $1,478.20