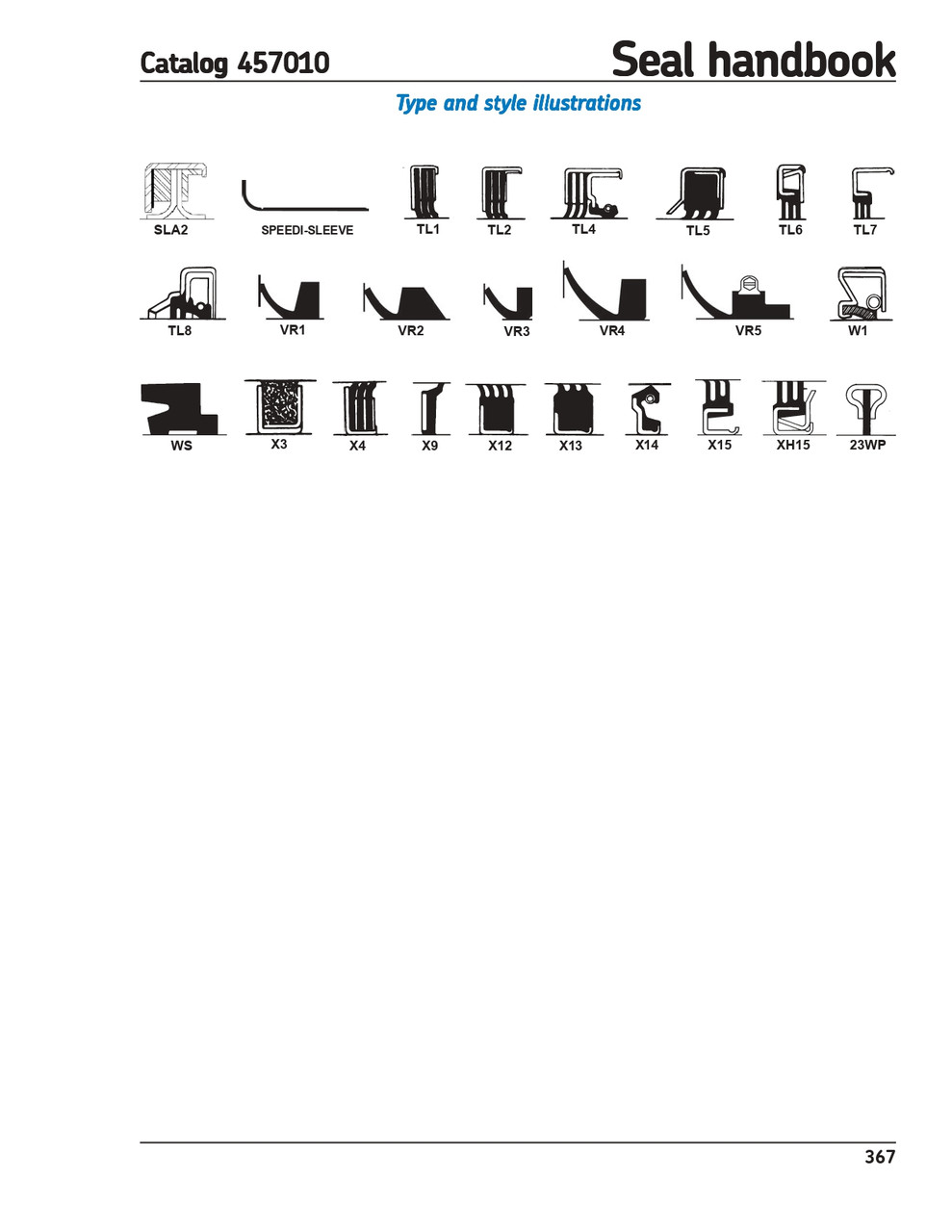

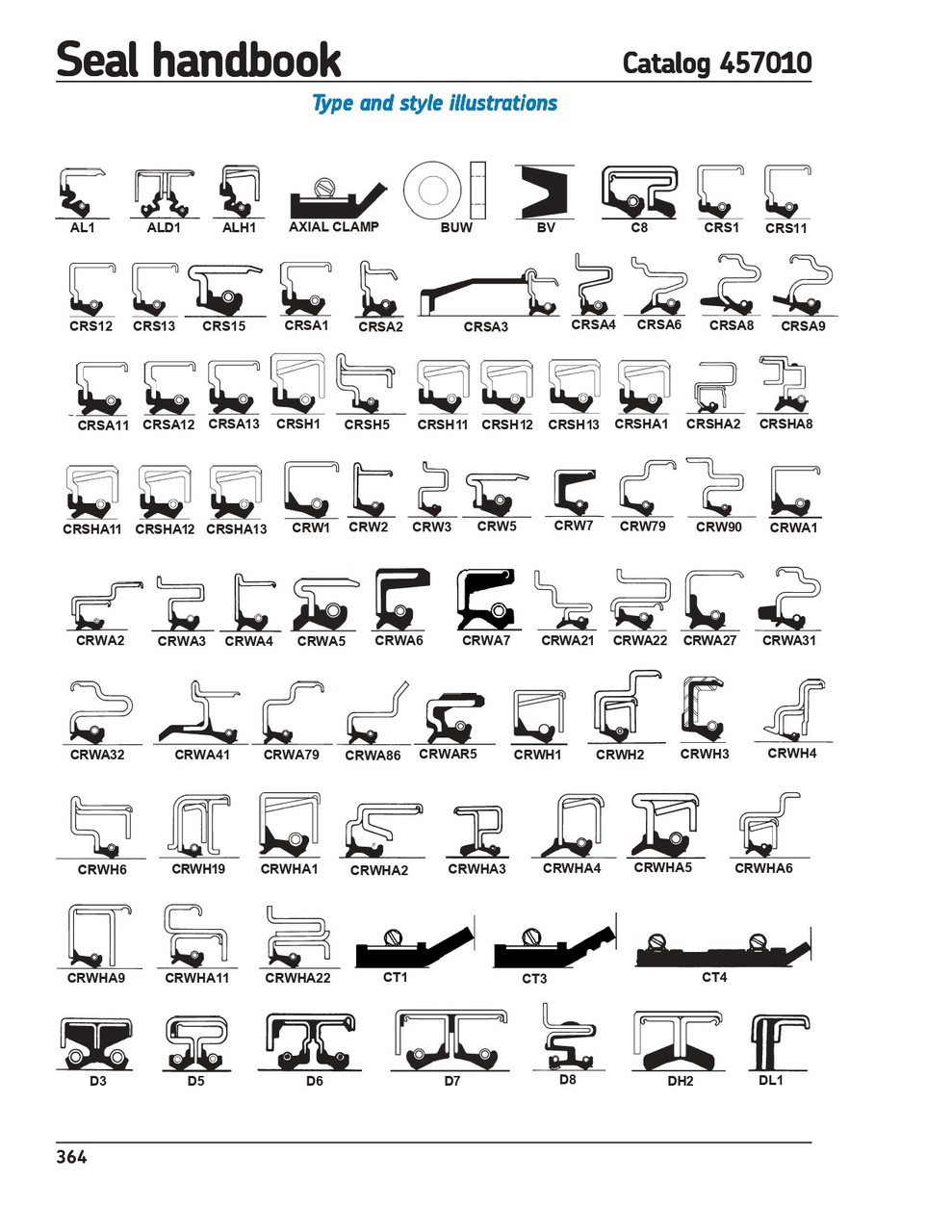

Product Description

Click this link for an online tool that offers three different ways of selecting and accessing SKF's large selection of seals. There is an interchange equating SKF oil seals to competitors part numbers, another feature is the ability to identify a seal by user inputed dimensions, and lastly one can simply enter a known SKF seal number to see its cross section profile and lip design.

Click this link for an online, multi-vehicle, bearing & seal application database.

For customers wanting to check SKF's oil seal cross compatibility with their largest competitor, National brand oil seals, please follow this link to access the National oil seal database provided by the Timken company.

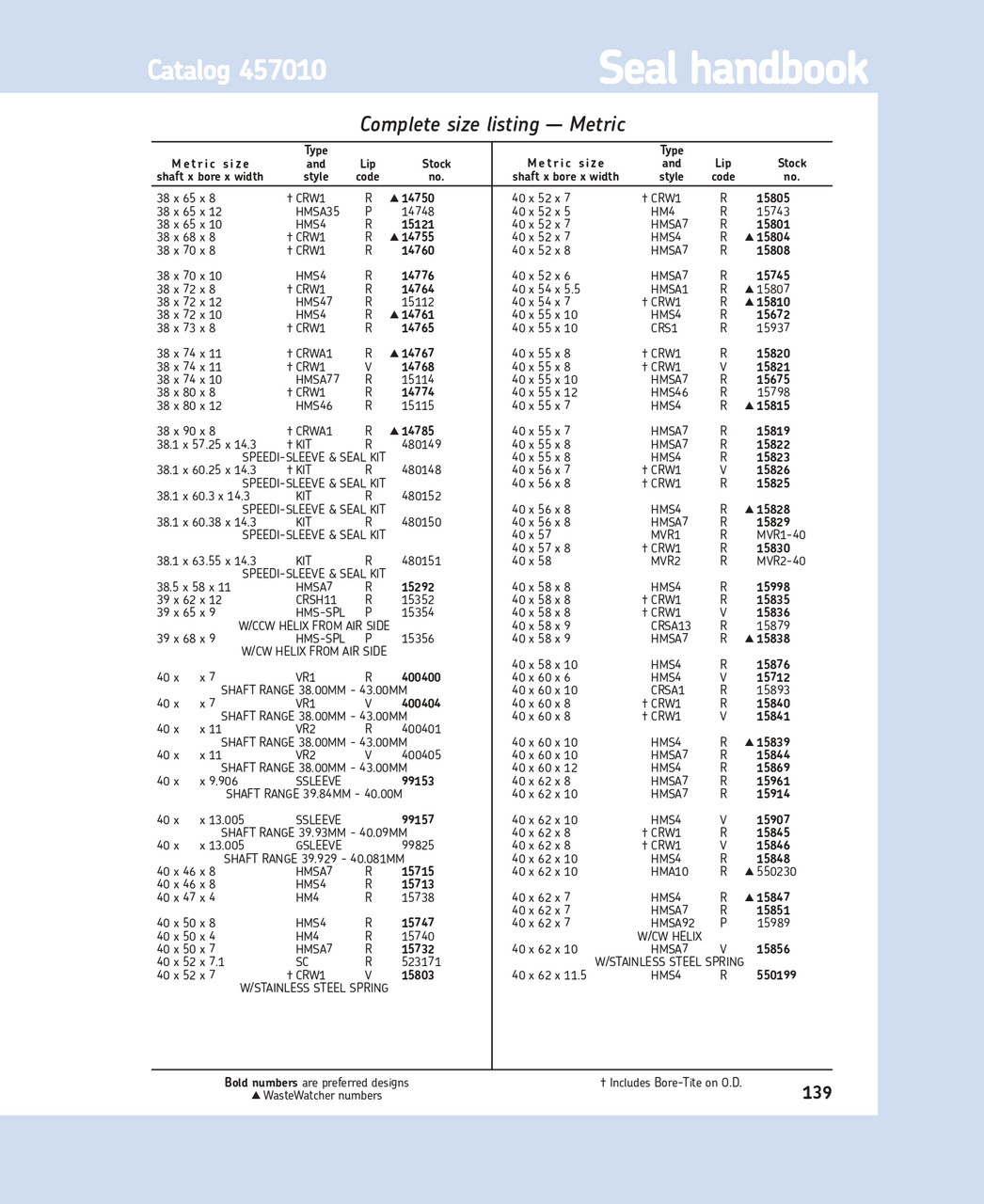

Nitrile (Lip code: R) is the most commonly used sealing material as nitrile is excellent with most mineral oils and greases. Variations are available for use with fuels, industrial fluids and highly compounded lubricants. Nitriles are recommended for operation at temperatures from -40° ~ 250°F (-40° ~ 121°C). Nitrile also works in dry running applications but only for intermittent periods. Some water based fluids however, such as some cutting fluids, can destroy the nitrile/plain steel bond when operating temperatures exceed 150°F (66°C). Please refer to pages 6A thru 15A in attached PDF catalog for chemical compatibility charts listed in alphabetical order

Bore-Tite® is a green tinted water based acrylic polymer. This green pliable sealant is applied to the outer case of select SKF seal part numbers and helps fill small imperfections in the housing bore when the seal is pressed into posistion. Bore-Tite® can withstand heat up to 400°F (204°C). It is resistant to most oils, greases, gasoline, mild acids, mild alkalis, aliphitics, salts and glycols. Bore-Tite® is NOT recommended with aromatics, ketones and alcohols; however splash contact that is wiped off will have little or no effect. The Bore-Tite® coating is .001 ~ .003" (.025 ~ .076 mm) thick but is not accounted for in the seals specified outer diameter

Please Note: Images provided are representative of the seals physical construction (unless otherwise noted). Some of the seal images depicted lip colors and/or bore finishes may differ from the actual specifications. Please refer to the seals accurate feature set listed above