- Home

- Products

- Green Line

- Fittings

- Crimp Fittings

- Ferrules

- 4 Wire

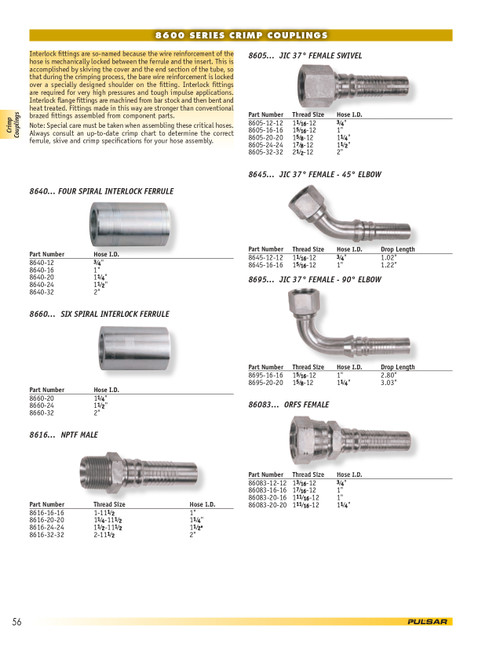

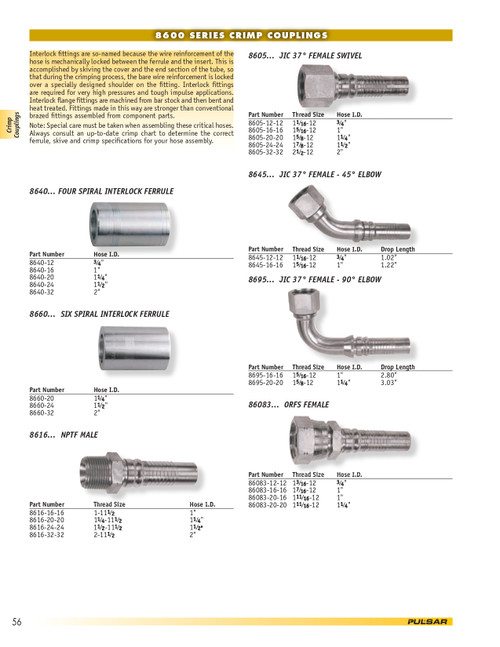

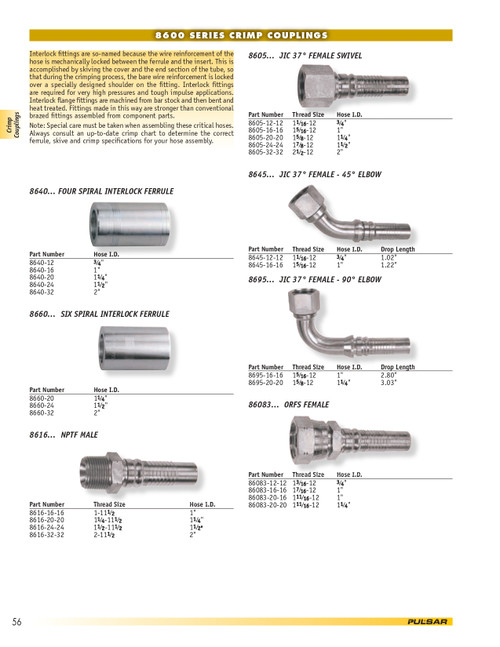

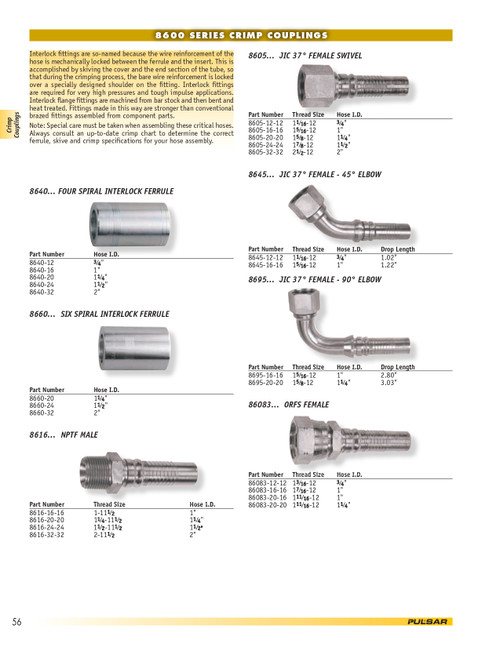

- Pulsar® 8600 Series

- 1" Pulsar 8600 Series Four Wire Interlock Ferrule 8640-16

1" Pulsar 8600 Series Four Wire Interlock Ferrule 8640-16

Greenline

Recommended

-

2" Pulsar 8600 Series Four Wire Interlock Ferrule 8640-32

MSRP:Now: $88.66