- Home

- Products

- Bearings

- Bearing Blocks

- Insert Bearing Blocks

- Pillow Blocks

- Corrosion-Resistant

- Polymer

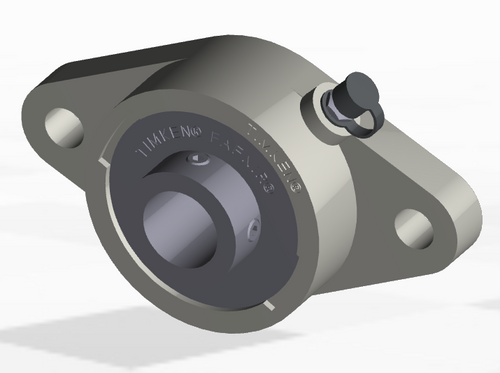

- 1-7/16" Survivor® Polymer Set Screw Pillow Block Assembly KAK1 7/16 PS

1-7/16" Survivor® Polymer Set Screw Pillow Block Assembly KAK1 7/16 PS

Timken

MSRP:

Now:

$253.75

(You save

)

- SKU:

- TIM KAK1 7/16 PS

- UPC:

- UPC 087796213425

- Weight:

- 1.38 LBS

- Bearing Type:

- Deep groove ball bearing

- Shaft profile:

- Round

- Bearing material:

- Stainless steel

- Housing material:

- Polymer

- Outer diameter profile:

- Spherical

- Locking device:

- Set screws

Bearing Type Deep groove ball bearing

Shaft profile Round

Bearing material Stainless steel

Housing material Polymer

Outer diameter profile Spherical

Locking device Set screws

Recommended

-

1-3/16" Survivor® Polymer Set Screw Pillow Block Assembly KAK1 3/16 PS

MSRP:Now: $228.72